This blog will go over the benefits of automated data collection!

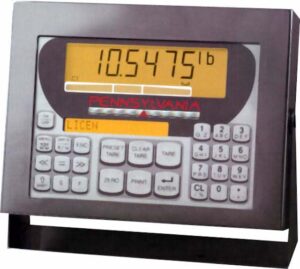

Companies collect daily data from essential parts of their operations, such as inventory, labor hours, quality control logs, and production. Weighing and counting scales can provide a necessary amount of this data. Still, many companies are missing a prime opportunity for automatically integrating their scale’s data into a digital format that will instantly provide real-time information for improving productivity while also processing efficiency. Read on to learn about the benefits of automated data collection!

Pencil and Paper Scale Data Collection Might Be Free, But It Can Cost You

A clipboard, a pencil, an Excel spreadsheet – having to manually enter process data, including weights and counts from your scales- is still a standard data collection system within plenty of manufacturing environments. While this method costs nothing to maintain, it quietly produces a few hidden costs across the enterprise. When personnel manually record their scale data, it takes time and is usually entered later into a computer. This means it passes through two people naturally prone to human error. It also takes those two people time to collect, document, and evaluate the data, which delays access to the data and slows down process improvements.

The True Cost of Manual Scale Data Collection

- Productivity killers such as breakdowns, downtime, and other minor problems go undetected because they’re not recorded or treated as irrelevant. Instead of accurate and objective data, you will receive subjective data from personnel who might be missing vital, actionable items for the job.

- Manual scale data collection takes some time. Your team might have to spend much of the shift on this task. Not only are mistakes easy to make and almost guaranteed to happen, but ordinarily productive people are tied up with inefficient and tedious tasks that can easily be replaced by a scale system that records this data automatically.

- Real-time information isn’t available. You are only getting backward-looking historical data. This “old” data makes quick reactions to production or process issues impossible due to the time lag between the event that happened and its assessment.

- Manually collected scale data could be more effective, consistent, accurate, and complete. Evaluations and improvements are based on old or flawed data that impairs higher productivity, better efficiency, and cost reduction.

CONTACT THE SCALE PEOPLE FOR WEIGHING EQUIPMENT AND CALIBRATION SERVICES!

Since 1956, The Scale People have earned a reputation as the best service provider for calibrating and repairing weighing equipment in the mid-Atlantic area. Our sales team can help you to find the best weighing equipment for your application. We currently have offices in Columbia, MD, and Newport News, VA, but we offer our services nationwide. Over the years, we have built many satisfied clients from various industries, including pharmaceutical, food and beverage, and government manufacturing. We are a fully ISO/IEC 17025:2017 accredited service company offering calibration for balances, scales, dynamometers, force measurements, test weights, pipettes, and more. All our services have a 100% satisfaction guarantee. We’re only a phone call away at +1 (800) 451-9593. Follow us on Facebook, Twitter, and LinkedIn to learn more about our work.